Our technologies

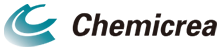

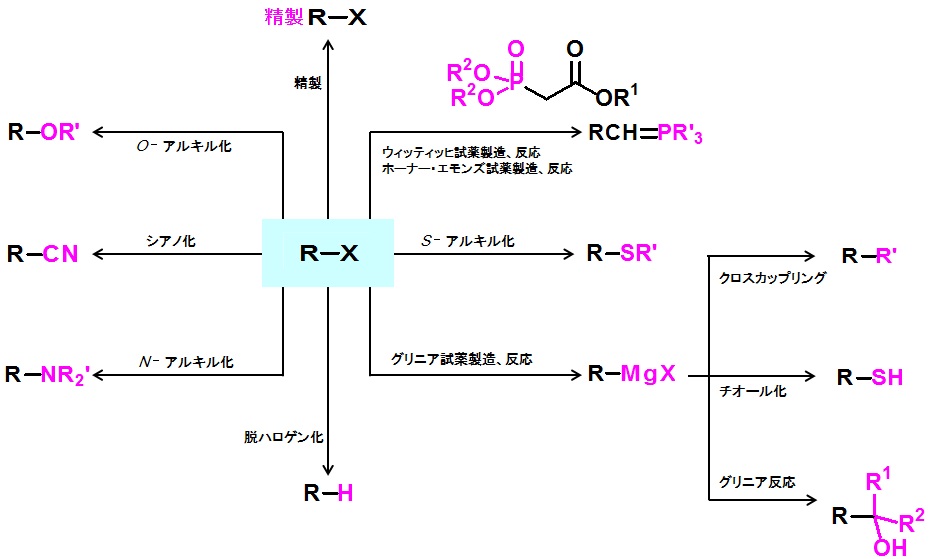

Bromination and chlorination

Bromination and chlorination have been Chemicrea's core technologies since its establishment and have been used to produce a wide range of products such as bromoacetic acid, esters, methyl bromide and isothiazolones. These reactions are currently used as fundamental technologies to many other products such as pharmaceutical intermediates.

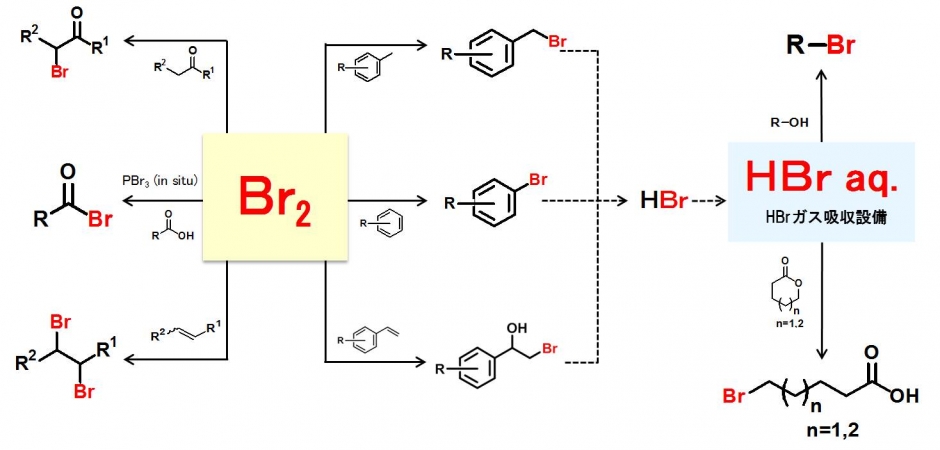

Conversion technologies for halogen compounds

Production of liquid API's ( Rectification under GMP control)

Heat medium rectification and fractionation, sampling, blending and filling in clean rooms

Handling corrosive and acidic substances (Rectification, GL pressure filtration dryer)

GL distillation equipments, gas absorption equipments, GL pressure filtration dryers, etc.

Filter dryer was newly installed in No.4 plant. May. 2018

Safe isolation of crystal from hydrocarbon solvent such as hexane is possible now.

Please don’t hesitate to ask us if you have any questions.

----------------------------------------------------------

- Material: Antistatic GL

- Size: 2.0m3

- Filtration area: 1.5m3

- Temperature condition: to 85℃ by heated water

- Vacuum: 2kPa

- Treatment volume : ca.600L

- Installation site: Clean-room, Class 100,000

----------------------------------------------------------

Thin film evaporator

Permitting distillation of highly heat-sensitive materials.